Aspirator

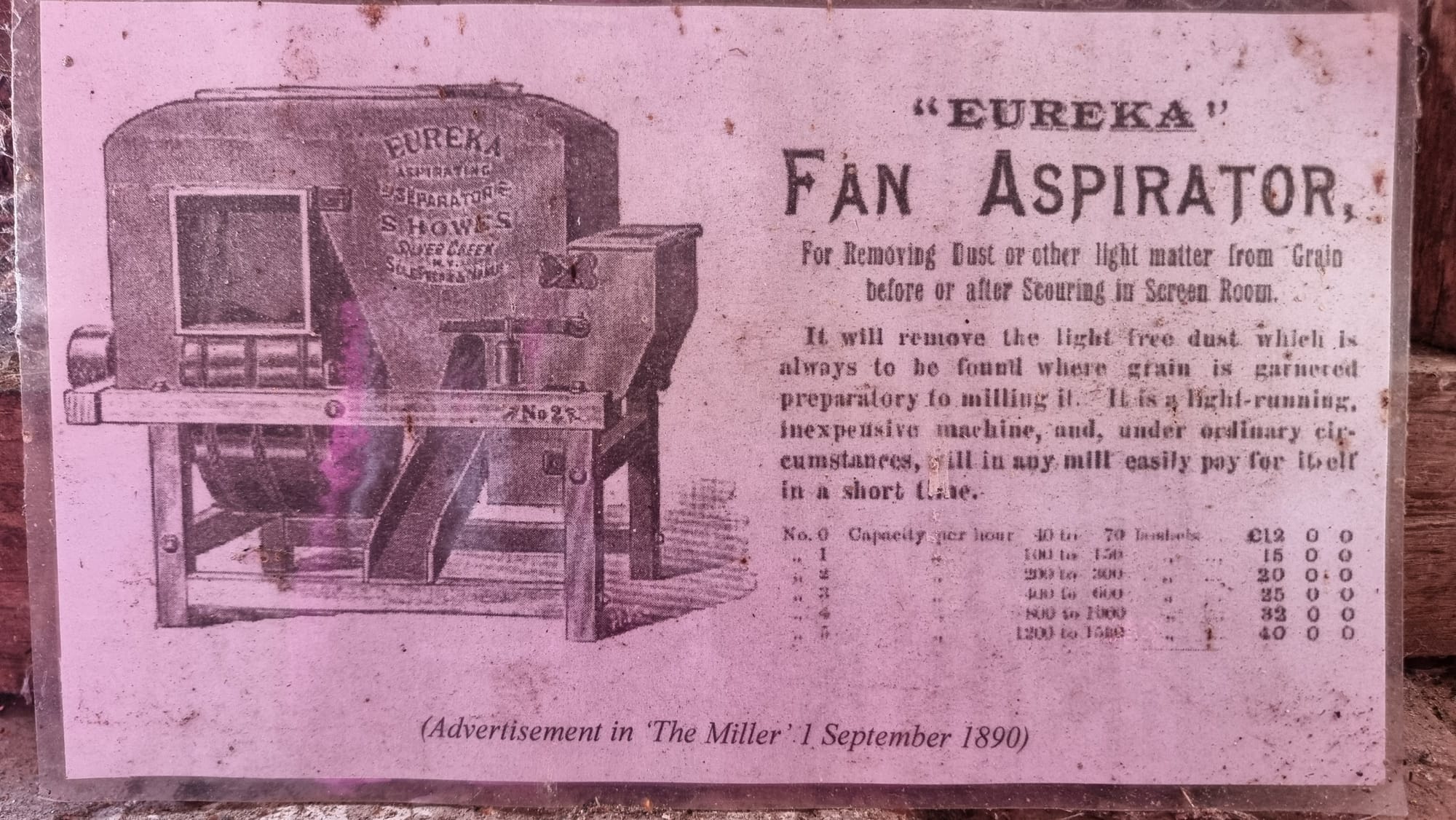

The "Eureka Aspirating Separator" is installed on the garner mezzanine floor. It is a machine designed to remove chaff from the grain before milling.

Our Aspirator was made in America in about 1905 by S. Howes of Silver Creek, New York. It was imported to England and installed in Rock Mill at Leamington Spa, near Warwick. After closure of the mill, it was transferred to New Hall Mill and located in one corner of the garner.

The Aspirator is powered via a line shaft, pulleys and a canvas belt from the ground floor and, apart from the millstones, it is the only machine to be powered by the waterwheel. The belt on the right of the machine drives a large internal fan to produce a strong updraft of air through the machine. The belt extends down to a gear on a drive shaft on the ground floor over the entrance door.

During our Open Days, grain is lifted up to the garner from the ground floor using the sack hoist, and is tipped into the aspirator for initial cleaning. You can clearly see the wooden funnel of the grain hopper to the top left. It is not part of the original machine.

When the hopper lever is operated, grain from the hopper falls through the upward flowing air current for an initial cleaning. The cleaned grain then falls through to a small storage bin feeding the winnower on the Stone Floor.

The 'stives', consisting of the chaff and any other light rubbish, are sucked away from the grain as it falls through the machine. Some are retained in a central waste section of the machine but the lightweight chaff passes through the fan and is collected in the 'stive room', the large separate area enclosed by sacking, from which it is later cleared. These days virtually nothing is collected behind the sacking, because the grain is already clean when it arrives at the mill.

Requests for more grain to be tipped into the aspirator hopper can be made by the operator of the winnower on the stone floor. The handle on a cord is pulled to ring a bell in the garner, hopefully to be followed by the sound of partially cleaned grain entering the small storage bin above the winnower. The grain can then be released into the winnower hopper as required for additional cleaning and sieving.